AVD-ROBO

Aluminium Vacuum Robotic Dosing Unit

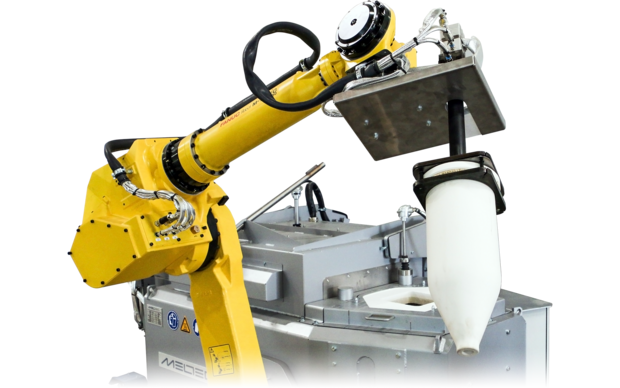

The aluminum vacuum robot dosing unit can be attached to any melting or holding furnace. It enables safe outtake and precise dosing of the aluminum melt into the filling chamber of the cold chamber die-casting machine. The dosing system essentially consists of a vacuum ceramic container, an evacuation device for sucking in the melt and a special closure at the sucking point. The vacuum ceramic container is made of non-sticking, temperature change-resistant and solid ceramic.

The mechanical movement takes place via a 6-axis robot system. This results in flexible solutions for foundries, even for complex casting processes. The system shows its strengths especially in applications in gravity casting for filling several molds or in rheocasting for melt pretreatment.

Meltec offers full robot integration into the vacuum dosing technology for all standard robot manufacturers.

The system shows the following advantages:

- Take in of melt below bath level – less oxides

- Filling of container by sucking in melt – less oxides

- Transfer of melt without air admission – less oxides

- Transfer of melt into a closed ceramic container – low drop of temperature

- High dosing accuracy through integrated, precise quantity measurement

- Flexible melt logistics through the use of robots

- Can be used for a wide range of casting applications - die casting, gravity casting, rheocasting, ...

Technical data

AVD-ROBO | Aluminium Vacuum Robotic Dosing Unit

| VDU | recommended dosing amounts [g] | dosing accuracy [g] * |

|---|---|---|

| 1000 | 100 - 1000 | ± 10 |

| 2500 | 750 - 2500 | ± 15 |

| 3000 | 900 - 3000 | ± 15 |

| 5000 | 1500 - 5000 | ± 25 |

| 10k | 4000 - 10000 | ± 35 |

| 15K | 6000 - 15000 | ± 45 |

| 20k | 8000 - 20000 | ± 60 |

| 40k | 12000 - 40000 | ± 100 |

| 60k | 18000 - 60000 | ± 150 |

| 100k | 40000 - 100000 | ± 300 |

| 100k-XL | 40000 - 100000 | ± 300 |

| 150k | 60000 - 150000 | ± 350 |

| 200k | 80000 - 200000 | ± 400 |