ZTS

Automatic Zinc Transport System

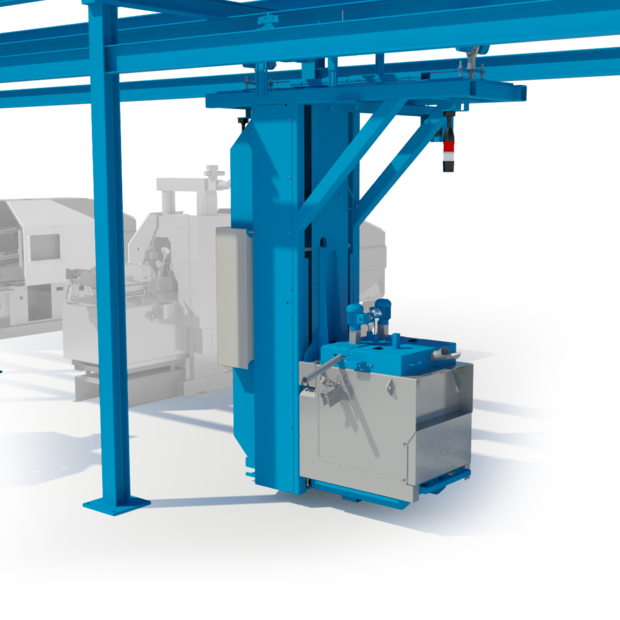

The next step in the terms of automation of zinc in-house recycling is the fully automated distribution of the zinc remelted in the ZRF Zinc Remelting Furnace to the hot chamber die-casting machines. For this purpose, Meltec has developed the ZTS Automatic Zinc Transport System.

The melted recycling material is pumped fully automatically into the ZTF transport furnace by the zinc feed pump in the melting furnace. Longitudinal transport takes place on a steel monorail construction using proven drive units from crane industry. This means that up to 24 hot chamber die-casting cells over a length of more than 50 meters can be filled with a liquid transport system. The height compensation is accomplished by means of an electric spindle drive.

The system is positioned sector by sector based on robust safety switches from crane industry in combination with optical precision sensors. This ensures robust, reliable and process-stable positioning logistics.

The zinc is then pumped fully automatically from the ZTF into the machine furnace using a zinc feed pump.

To secure the travel path, the ZTS liquid transport system has up to 4 safety lasers. In combination with the secure signal transmission via radio, complete flexibility is guaranteed.

The system shows the following advantages:

- Fully automatic and safe pumping over of the molten zinc from the ZRF

- Low heat loss, highly efficient insulation materials

- High energy savings through liquid transport

- Cost savings through automated distribution and improved process reliability of the die casting cells.

- Safe transport thanks to modern safety laser technology

Technical data

ZTS | Automatic Zinc Transport System

| ZTS | crucible content [kg] | usable content [kg] | heating capacity [kW] | distribution capacity [kg/h] |

|---|---|---|---|---|

| 650 | 650 | 450 | 9 | 900 |