MVDF

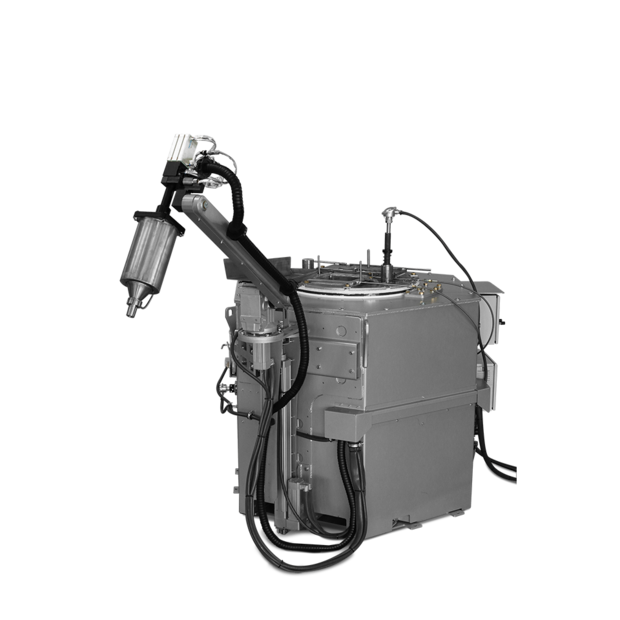

Magnesium Vacuum Dosing Furnace

The crucible furnaces are designed for melting and holding magnesium die-cast alloys. The high-quality insulation leads to very low energy consumption and thus low operating costs. By positioning the furnace on the base floor, there is very good access to the furnace and the care of the melt is easily possible. Special steel crucibles are used for the furnaces, which allow the magnesium alloy to be melted indirectly. The heating is provided by the heating bands integrated in the furnace chamber, which are characterized by their high performance and durability. Changing the heaters can be carried out without any problems. The heating bands are controlled via thyristors, which keep the melt at the right temperature without overheating.

The dosing system consists of a heated vacuum steel container, an evacuation device for sucking in the melt and a special closure at the suction point.

The mechanical movement takes place via a servo-controlled lifting and swiveling device.

Fully integrated protective gas mixing systems guarantee the safe and technologically optimized magnesium dosing process.

The system shows the following advantages:

- Take in of melt below bath level – less oxides

- Filling of container by sucking in melt – less oxides

- Transfer of melt without air admission – less oxides

- Transfer of melt into a closed and heated steel container – no drop of temperature

- High dosing accuracy through integrated, precise quantity measurement

- Easiest maintenance of dosing system and furnace

- Energy-efficient and economical process

Technical data

MVDF | Magnesium Vacuum Dosing Furnace

| MVDF | melting capacity [kgMg/h] * | usable crucible content [kg] | heating capacity [kW] | recommended dosing system sizes |

|---|---|---|---|---|

| 500 | 200 | 550 | 85 | VDU1500 |

| 800 | 300 | 820 | 120 | VDU5000 / 10k |

| MVDU | recommended dosing amounts [g] | dosing accuracy [g] ** |

|---|---|---|

| 1500 | 100 - 1500 | ± 15 |

| 2500 | 300 - 2500 | ± 25 |

| 4000 | 500 - 4000 | ± 30 |

| 10k | 3000 - 10000 | ± 45 |