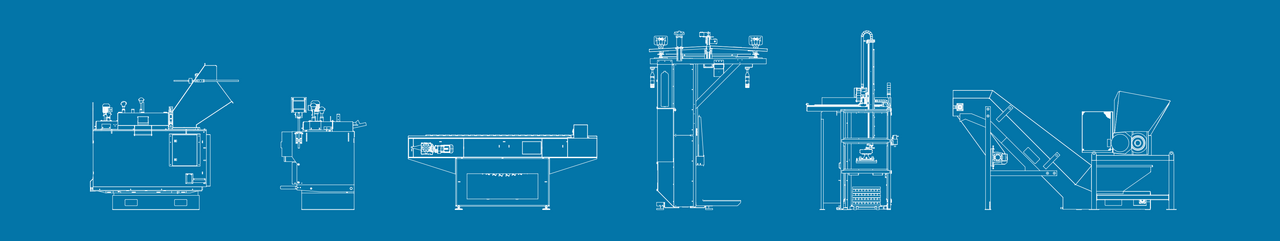

Zinc

Runners and defective parts accumulate in foundries.

This material can be economically recycled in a modern, central in-house recycling system. High external recycling costs, storage and transport costs can be prevented. The process starts with the collecting and feeding of the recycling material by use the feeding conveyor belt FCB, afterwards the melting in the Zinc remelting furnace ZRF and ends with liquid transport ZTF to the machine furnace or with the production of ingot via the ingot casting device ICD.

ZTF

Zinc Transport Furnace

The system shows following advantages:

- Simple and safe pumping over of the molten zinc from the ZRF

- Low heat loss, highly efficient insulation materials

- High energy savings through liquid transport

- Safe and ergonomic transport using a pallet truck

- 24V power supply directly from the pallet truck

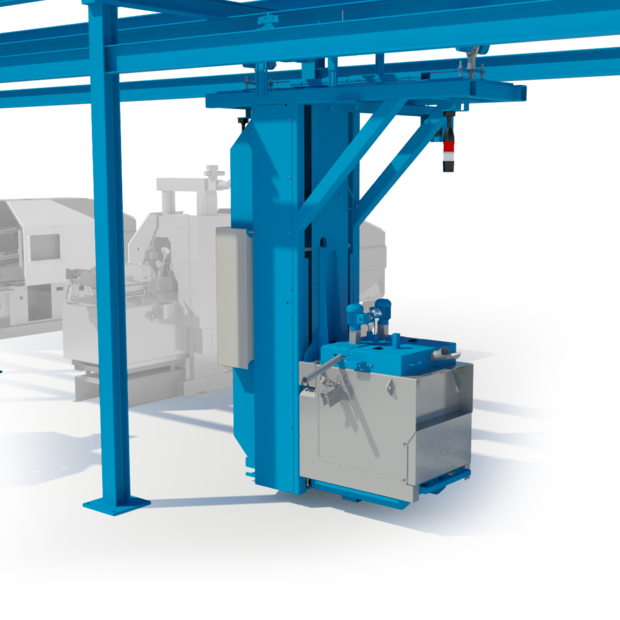

ZTS

Automatic Zinc Transport System

The system shows the following advantages:

- Fully automatic and safe pumping over of the molten zinc from the ZRF

- Low heat loss, highly efficient insulation materials

- High energy savings through liquid transport

- Cost savings through automated distribution and improved process reliability of the die casting cells.

- Safe transport thanks to modern safety laser technology

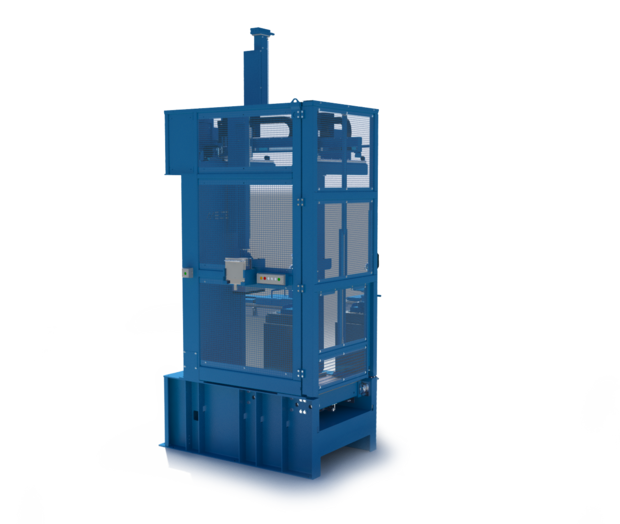

IAD

Ingot Automatic Destacking Unit

The system shows the following advantages:

- Easy loading of entire stacks of ingots

- Precise laser detection of ingot dimensions and positions

- Fully automatic depalletizing

- Constant furnace filling leads to better temperature consistency and higher melting capacity

- Unattended operation up to 8 hours

- Improvement of ergonomics and work safety

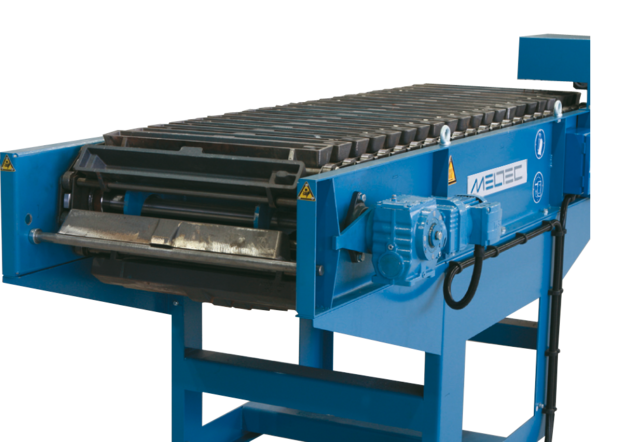

FCB

Feeding Conveyor belt

The system shows the following advantages:

- Fully automatic and safe filling of the recycling material into the ZRF

- Increase in melting capacity through continuous filling

- Cost savings through automated filling process

- Improved remelt performance and reduced maintenance effort when using a shredder